Tyre Regulations

Ensuring Tyre Safety through Robust & Comprehensive Regulations

Tyres play a pivotal role in vehicle safety, being the only contact point between a vehicle and the road. ETRMA is dedicated to upholding the highest safety standards, working closely with EU policymakers to ensure comprehensive regulations that enhance road safety.

The EU has established stringent tyre regulations to safeguard drivers, passengers and the environment. These regulations encompass essential aspects such as:

- Tyre Construction and Materials: Ensuring durability and resilience under various conditions as well as progress towards increasingly sustainable products, including their circular economy.

- Performance Standards: Including criteria for wet grip, noise emissions, rolling resistance, and tyre abrasion.

- Type Approval and Compliance Testing: Guaranteeing that all tyres meet the required safety standards before they reach the market.

The UNECE 1958 Agreement standardizes these requirements across member countries. Key regulations include:

- Passenger Car Tyres: UN ECE Regulation 30

- Truck Tyres: UN ECE Regulation 54

- Motorcycle Tyres: UN ECE Regulation 75

- Agricultural Tyres: UN ECE Regulation 106

- General Safety Regulation (EC-661/2009) Adopted in 2009, this regulation harmonizes technical requirements across the EU, covering safety and environmental standards, including tyre contributions to CO2 reduction and road safety. The regulation was updated in 2019 ((EU) 2019/2144) to extend the requirement for tyre pressure monitoring systems to commercial vehicles.

- The technical requirements set in this Regulation are established at UNECE Level by Regulation 117and its successive amendments.

EU regulations complement and often translate in EU law Regulations established at UN ECE level. The tyre industry is global and, as such, needs global regulations. It is for this reason, that regulatory cooperation under the UN 1958 Agreement is of fundamental importance to avoid barriers to trade when accessing third countries.

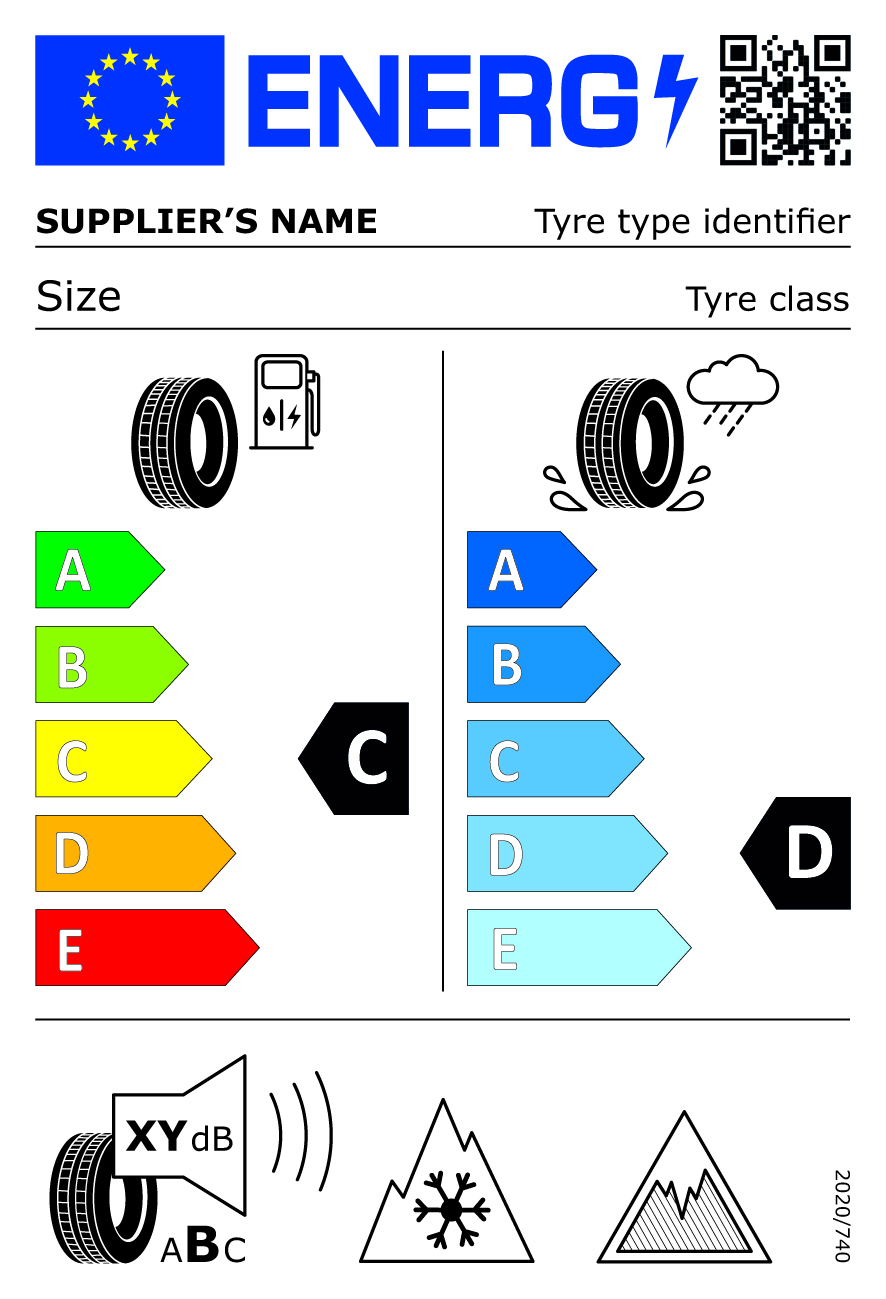

Understanding Tyre Labelling

The Tyre Labelling Regulation has been in place since 2012 and provides consumers with transparent and objective information about tyre performance, enabling informed purchasing decisions. The EU tyre label displays three key performance indicators:

- Fuel Efficiency: Measured by rolling resistance, contributing to lower fuel consumption and reduced CO2 emissions.

- Wet Grip: Indicating the tyre’s ability to maintain traction on wet surfaces, a crucial factor for road safety.

- Noise Emissions: Reflecting the external noise generated by the tyre, which impacts overall driving comfort and environmental noise pollution.

By understanding these labels, consumers can select tyres that best meet their safety and performance needs.

Thanks to the EU tyre label, EU consumers will be able to choose more fuel-efficient tyres, which can lead to great savings for both commercial and end users in terms of costs and emissions. Road safety is improved through better wet grip while information on noise levels helps reduce traffic-related noise pollution.

Easier access to information for the consumer: via the QR code that quickly allows the consumer to access the EPREL database (European Product Registry for Energy Labelling), all the tyres’ information will be available at a click.

LIZEO Study

Since tyre labelling has been introduced in Europe, its biggest challenges have been the lack of market uptake of high-grade tyres and its enforcement.

The study carried out by Lizeo Group between 2012 and 2020, found that tyres rated A-A in both rolling resistance and wet grip are less than 1% of the market. This data is in line with what the European Commission found in its own assessment before the revised regulation was published. It appears that the tyre label is still a young tool and the market still has to fully appreciate the benefits brought by the use of tyres with the best combinations of rolling resistance (fuel efficiency) and wet grip performance (road safety).

The EU label is confronted with an evolving market: the overall market did not progress in terms of label over the years, but we have seen an increasing number of new brands in the market (+43%), in the budget segment. This is a clear indication that, still consumers continue choosing their tyres mainly on the basis of price.

Furthermore, it is apparent that there is still little appreciation of the fact that tyres are technologically complex products. Their development faces multiple sets of customer-oriented performance requirements, which often conflict with each other and require complicated engineering developments. For example, it is a huge technological success to be able to create high grade tyres both for fuel efficiency and safety.

Market surveillance is the cornerstone of an effective implementation. ETRMA supports all measures that strengthen market surveillance through sanctions and penalties, increase the visibility of the label – especially concerning distant selling – and introduce stronger obligations for Member States.

Tyre & Road traffic noise

The European tyre industry recognises the need to contribute to the reduction of noise pollution and is committed to work with all the key stakeholders to make this development a success.

Significant progress has already been made over the last 15 years by the tyre industry to reduce the rolling noise by up to 5dB, more than halving sound emissions.

Road traffic noise is caused by a combination of different elements and in particular of rolling noise (linked to the interactions between the tyre on the vehicle and the road surface) and propulsion noise (originating from the engine itself). When considering cars, in general, above certain speeds the noise generated by tyre-road interaction becomes more relevant.

To both secure effectiveness and market surveillance while properly driving the design, there is urgency to work on measurement uncertainty: the high majority (95%) of all measured values will be in the range of -2.3 dB to +2.3 dB (UNECE Task Force Measurement Uncertainty) around the true noise level of the tyre. Industry has initiated a concrete work plan to reduce significantly such uncertainty of tyre noise regulatory test methodologies. This will actually develop a better enforcement tool, allowing to remove from the roads those noisy tyres, which due to the test uncertainty, are currently in the market (ETRMA report Tyre & Road traffic noise, Where we should look for road traffic noise improvements, December 2021).

Furthermore, Industry underlines the importance of a holistic approach in effectively tackling traffic road noise, in the context of the balanced safety and environmental performances of vehicles to successfully contributing to the European Commission road safety Green Deal ambitions.

As already specified in April 2017 in the European Commission report “FUTURE BRIEF: Noise abatement approaches”, road surfaces can have a significant influence on the sound produced by vehicles travelling on them and the benefits of low noise tyres are positively enhanced when applied on noise-reducing road surfaces.

We believe that the road system could bring relevant value in a truly holistic approach to mitigating traffic road noise.

To learn more please click here.

Retreaded Tyres

Retreaded tyres, which have replaced tread, are regulated by EU and UNECE standards. The new tyre label, provisionally agreed upon in November 2019, will also cover retreaded tyres. To assess the technical feasibility of these labels, the European Tyre and Rim Technical Organization (ETRTO) conducted an extensive research program focusing on rolling resistance, wet adherence, and rolling noise emissions.

Three experiments based on Regulation 1222/2009 and standards for new tyres (EC 661/2009) were conducted to:

- Check the impact of the collected casing on the rolling resistance of retreaded tyres.

- Assess the manufacturing process’s impact on rolling resistance, wet adherence, and rolling noise emissions.

The findings and data from these experiments support the European Commission’s intention to label retreaded C3 tyres for commercial vehicles, assuming suitable measurement methods are defined as per EU regulation 2020/740.

In October 2022, ETRMA, ETRTO, and BIPAVER submitted a proposal for sustainable labelling schemes for C3 retreaded tyres to the European Commission. [See more in this document]

Winter tyres obligations

The obligation to fit vehicles with winter tyres differ greatly across Europe as it depends on regulations established at national, or sometimes even regional, level.

EU legislation requires that winter tyres for use in severe snow conditions exhibit a minimum level of performance on snow for both braking and traction. If a tyre passes the respective test, it can be marked with the three-peak mountain snowflake symbol.

Vehicle Energy Consumption Calculation Tool (VECTO)

The Vehicle Energy Consumption Calculation Tool (VECTO), alongside the Monitoring and Reporting Regulation and the HDVs CO2 Standards, forms the legislative framework for Heavy Duty Vehicles (HDVs).

Since January 2019, all new HDVs must have CO2 certificates. Tyre rolling resistance coefficients must be reported to ensure market transparency regarding CO2 emissions and fuel consumption.

Euro 7

The Euro 7 regulation was formally adopted in April 2024, setting a framework to limit tyre abrasion emissions for the first time in Europe and aligning with the work of the UNECE World Forum for the Harmonization of Vehicle Regulations (WP.29).

The UNECE Working Party on Noise and Tyres approved the methodology for measuring tyre abrasion for passenger car tyres (C1 tyres), under UN Regulation No. 117.

The tyre industry is significantly investing in a market assessment exercise which is leveraging the UNECE methodology to collect abrasion data from diverse tyre sizes, patterns, and brands already on the market to propose tyre abrasion limits.

The double UNECE – Euro 7 process will unfold as follows:

By September 2025 – Tyre abrasion limits for passenger car tyres (C1 tyres) will be incorporated into UN Regulation No. 117.

2026 – EU regulators will use the UNECE methodology and market assessment to determine C1 tyre abrasion limits. This involves passenger car tyres (C1), but the exact implementation date of the limits could still depend on ongoing regulatory discussions.

2026-2027 – The UNECE measuring method for tyre abrasion is expected to be extended to heavier vehicles (C2 for light commercial vehicles and C3 for heavy-duty vehicles), allowing the regulation to expand to these categories.

2028 – Euro 7 tyre abrasion limits for new passenger car tyres will come into force.

2030 – Euro 7 limits for existing passenger car tyres and light commercial vehicle tyres will come into force.

2034 – Euro 7 limits will apply to heavy vehicle tyres.